What is Stainless Flex Hose?

Stainless flex hose is a highly flexible hose that has a flexible structure and is made of stainless steel. It is generally called "flex" because it has the ability to bend and stretch metal. It has a structure knitted from stainless steel wires and covered with a protective coating from the outside.

Where are Flex Hoses Used?

Stainless flex hoses are generally used to transport liquid, gas or steam. It is resistant to high temperatures and pressures and resists corrosive substances. Thanks to these properties, they are used in various industrial applications.

Some common uses of stainless flex hoses are:

Water and gas plumbing: Used in water and gas plumbing systems in homes or commercial buildings. Thanks to its flexible structure, the installation and assembly of the installation becomes easier.

Heating, ventilation, and air conditioning (HVAC) systems: Used to transport heating and cooling water in HVAC systems. Thanks to its flexibility, it adapts to the installation.

Automotive industry: Used to evacuate exhaust gases in vehicles. It is resistant to high temperatures and remains flexible against engine vibrations.

Chemical industry: Used for transportation of chemicals. Stainless steel structure provides resistance to chemicals.

Food industry: Used to transport liquids and gases in food processing plants. Its stainless steel structure meets hygiene requirements and makes it safe when in contact with food products.

These are just some areas where stainless flex hoses are commonly used. Their range of applications is quite wide and they can be preferred whenever a flexible pipe is needed wherever it is needed.

Stainless Steel Hoses

Flexible metal braided hoses can be easily used in a wide variety of systems such as water, steam, hot oil and gas, with their pressure resistance and bendable structure. Conveying liquids, compensating for problems arising from installation, absorbing vibration and expansion are some of the usage purposes of metal braided hoses. Parallel, open and closed joint options are available, and increasing the resistance of the hoses to pressure and external influences can be achieved by knitting a double layer.

Stainless Steel Flexible Hose Components:

Stainless Wire, Connection Flange, Welding Neck Coupling, Threaded Coupling, Threaded Nipple, Hose Inner Layer

Stainless Steel Hose Application Areas:

•Iron and steel industry / Steel Industry

•Oil and gas installations / Petrochemistry and Gas Installations

•Chemist Industry

•Heating and cooling systems / Heating & Cooling Systems

•Food industry / Food Industry

•Automotive industry / Automotive Industry •Paper production facilities / Paper Industry

•Ship industry / Ship Building Industry •Defense industry / Defense Industry

•Moving systems / Moving Systems

•All types of warehouse and tank connections

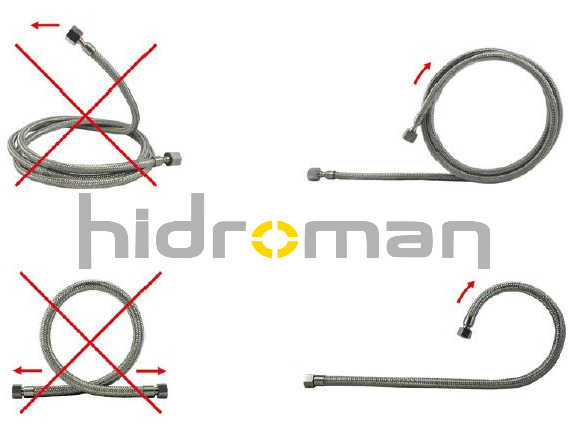

Factors That Shorten the Life of Stainless Flex Hoses

•Cycle life is the number of times the hose returns to the point where it started in its one-way movement. Various reasons affecting cycle life are listed below.

•Improper Assembly

•Incorrect Working Pressure

•Incorrect Operating Temperature

STAINLESS FLEX HOSE MANUFACTURING STAGES

Flex Hose begins its journey in manufacturing with its chemical content, cut, flatness, thickness, surface quality, etc. It starts as a “stainless strip sheet”, many of which are produced with great precision.

Then, in a production line, TIG, Laser, Plasma etc. It is welded continuously by one of the methods and becomes a pipe. Then, it leaves the line on the same line, with its joints formed by mechanical or hydraulic forming and becoming flexible. Afterwards, it is immediately subjected to the first sealing test.

If, after this stage, it is only subjected to wrapping and packaging and shipped directly, as is the case with solar flexes, the hose has now turned into a product. If the product is to be delivered as a "flexible hose kit", it must visit one or more of the MAIN processing stations briefly mentioned below. In this process, semi-finished products are subjected to leakage tests one or more times. This means that each product, without exception, will be tested at least 2 times in total.

HİDROMAN produces Stainless Flex Hoses meticulously.

1- Nipple, bobbin (for use with welded connecting piece-nut) etc. welding of end pieces

– All kinds of flexible hose kits

2- Knitting from stainless steel wire

– 14800 stove flexes

3- Annealing (For easier bending and 100% more extensibility)

– 15266 Indoor installation flexes

– 11353 Extendable flexes

4- Coating of tubing (insulation) with transparent or opaque PVC, polyolefin/polyethylene, pvc+polyethylene foam materials

– 14800 Furnace Connection Flexes (Transparent PVC)

– 15266 Indoor installation Flexes (Opaque PVC)

– 10670 Combi Connection Flexes (Polyethylene/Polyolefin)

– 10878 Meter Flexes (Polyethylene / Polyolefin)

– 11353 Extensible Flexes (Polyethylene/Polyolefin)

– Solar Flexes (PVC + Polyethylene sponge)

5- Closing

– 11353 Extendable Flexes

General Information

2'' - 200 cm - Stainless Steel Braided - Wire braid is made of stainless steel, elbow and nipple parts are made of galvanized steel, clamp parts are made of galvanized steel.

Hidroman Elbow Flexible Hose Pas. Steel 2'' - 200 cm

Since flexible connection hoses made of stainless braided material can be used in both hot and cold water, they provide great convenience and speed in both expansion tank connection in heating systems and balance tank connection in booster systems. It is extremely easy to install and remove tanks connected with flexible hose. It saves time and labor. Hoses braided with aluminum or stainless wire are extremely durable. Since EPDM inner hose is used, it is extremely hygienic. Our hoses have a structure that does not allow the production of bacteria, so they are healthy, can be used in drinking water and do not cause odor.

One side of the flexible hose is elbow type, the elbow side has a movable fitting, the other side is straight type and has a male nipple connection.

The length of the flexible hose is measured from the very end of the nipple side to the record part, including the elbow.

Flex length should be determined according to the size of the tank and its distance from where it will be connected.

* This 200 cm model can be used in expansion or booster tanks of any brand with a 2'' lower connection.