Seide Large Hydraulic Cylinder Repair Machine Advantages (Disassembly, Assembly and Test Bench in One)

Cylinder Dismantling Machine For Large Cylinders:

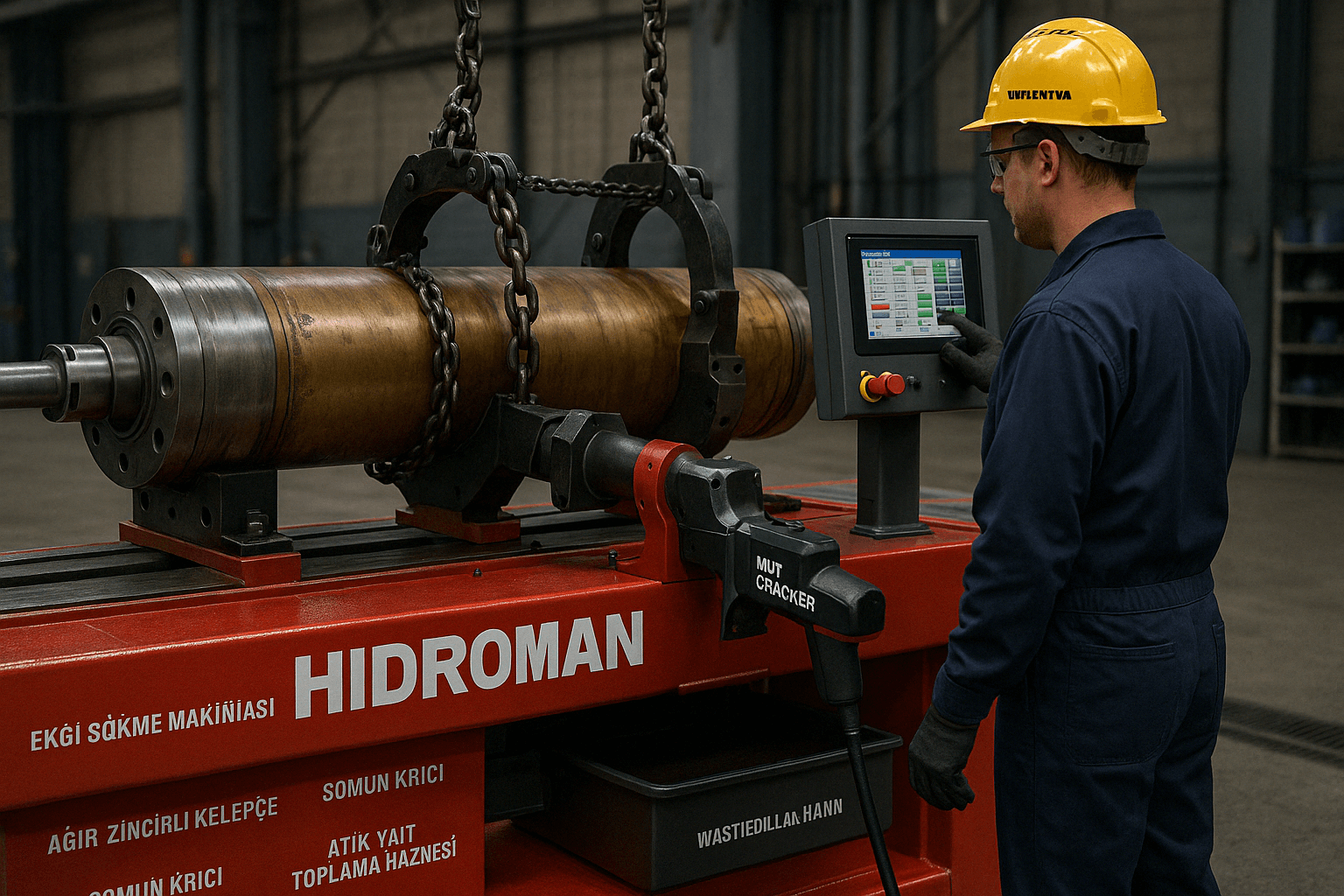

Dismantling large cylinders is a process that often requires heavy work and specialized equipment. Therefore, proper disassembly of large cylinders is critical for both operator safety and proper repair of the cylinder. Here are the main features and advantages of this type of machine:

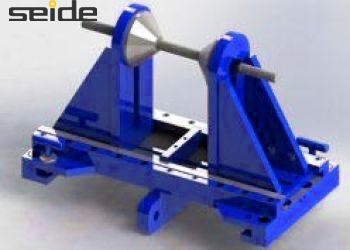

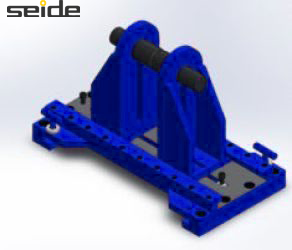

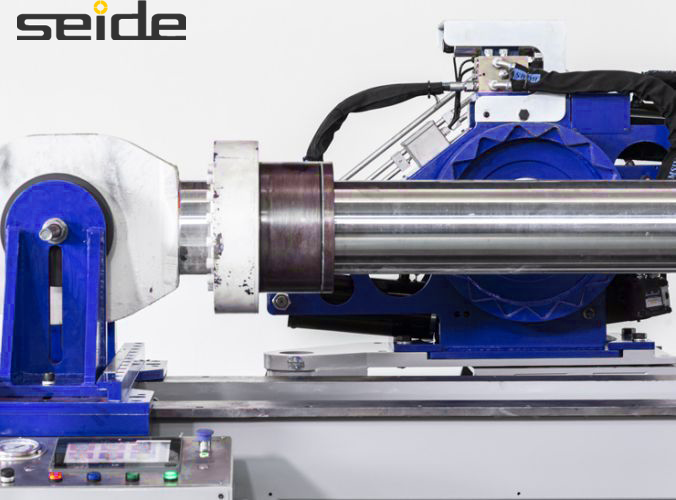

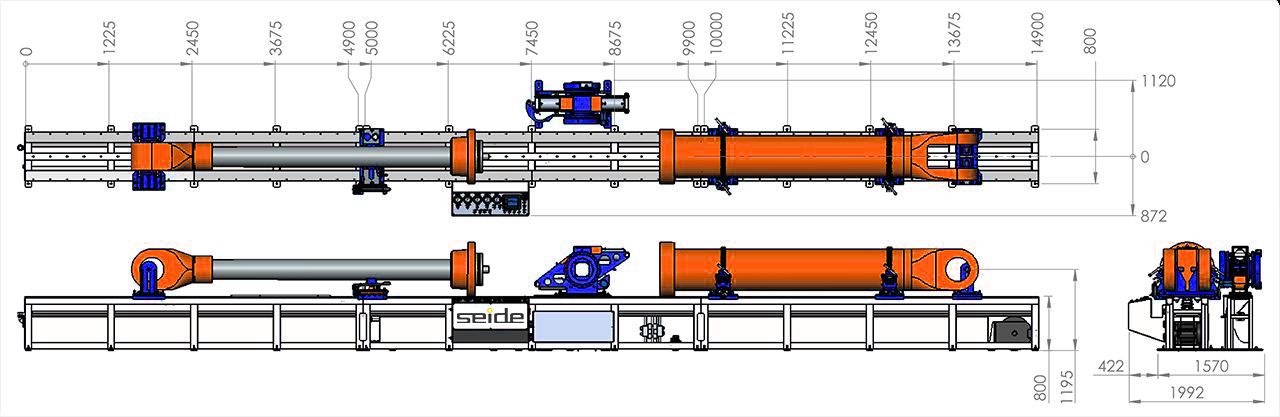

Robust and Full-Length Bench Design: Provides more usable workspace and offers flexibility to accommodate additional repair functions. This design is suitable for large and heavy cylinders (with a fixture capacity of 6000 kg/fixture). The strong design extends the life of the machines and improves operator safety.

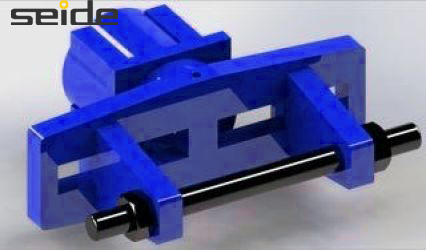

Vehicle Sliding Plates and Height-Adjustable Chain Fastening Tools: Allows the cylinder or rod configuration to be securely placed on the machine and adjusted to a common vehicle center height. This offers the user maximum flexibility when it comes to disassembling and assembling all types of cylinders.

PLC Control Display HMI: Used to control machine functions and system limits (e.g., piston nut torque presets). It also includes warnings about operator safety. Optional Feature.

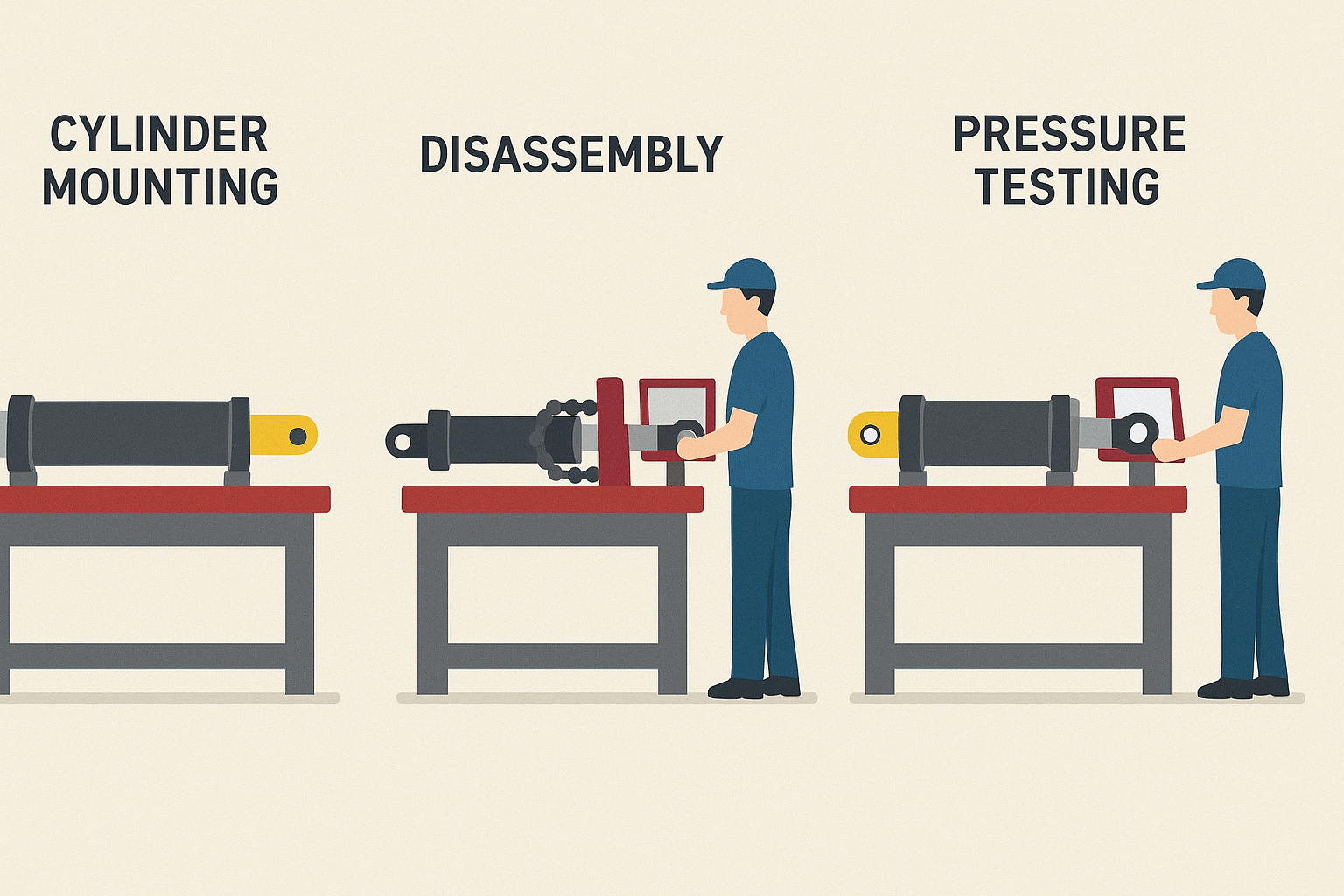

Integrated Cylinder Pressure Test Function: Digital export of cylinder test results is provided. The optional Linear Encoder supports stroke length measurement and automated multi-point cylinder test protocols.

True "Single Operator" Function: Best-in-class operator safety is ensured.

Optional Wrench Turntable: Makes it easy to access the piston nut without turning the piston rod or removing the cylinder body. It offers a more efficient solution than competing products.

Nut Unscrewing Mechanism: It uses a simple and effective gear mechanism for maximum strength. It works with a hexagonal socket type adapter up to 345 mm for piston nuts.

Reverse Joining: Rejoining is done by reverse rotation using the same tools. Precise control over system pressure allows nuts to be retornized to OEM (Original Equipment Manufacturer) specifications. This is done by torque presets entered into the HMI.

Affordable Tools: Tools that can be easily installed and used. Vehicles can be purchased individually as needed. Tool inserts can be made for customized jobs.

Modular Bench Design: Can be expanded if needed.

Full-Length Oil Collection Tray: Provides a clean operation. The oil collection system captures the remaining oils in the cylinder and transports them to the waste oil reservoir. This reduces cleaning costs and increases safety in the workplace.

Low Machine Cost, Low Vehicle Cost, Easy Installation: Safer, cleaner operation and greater flexibility make more efficient use of your equipment investment and floor space.

These advantages show that the Seide Hydraulic Cylinder Repair Machineoffers an effective solution that increases efficiency, ensures safety and reduces operational costs, especially in maintenance and repair work.

How Does a Hydraulic Cylinder Repair Machine Work?

Hydraulic Cylinder Repair Machine is a machine specially designed for dismantling, assembling and testinghydraulic cylinders . This system is used to perform transactions both safely, efficiently and accurately.

Operation Steps

Hydraulic Cylinder Repair Machine Technical Specifications Table

|

Properties |

SDE-5000 |

SDE-4000 |

|

Control Type |

Full Electronic Control |

Electro-Mechanical Control |

|

HMI / Display |

Windows Based |

- |

|

Pressure Test Capacity |

300 Bar |

200 Bar |

|

Pressure Testing PC Transfer |

There is |

Image Only |

|

Internet Connection |

LAN |

No |

|

Wireless Controller |

There is |

No |

|

Nut Unscrewing |

Standard |

Optional |

|

Torque (Hydraulic Denut) |

130'000 nm |

65'000 Nm / 130'000 Nm |

|

Rod Capacity |

7 Tons |

7 Tons |

|

Hydraulic Power Input |

There is |

No |

|

Bench Extension (5m) |

X |

X |

|

Nut Unscrewing Turntable |

There is |

There is |

|

Laser Stroke Measurement |

Standard- Hydraulic |

Optional- Manual |

|

High Pressure Test Unit |

There is |

No |

|

Side Flow Filtration (1613 Std) |

Optional |

Optional |

|

Oil Condition Monitoring |

Optional |

Optional |

|

Nut Unscrew Update |

65’000 Nm Upgrade |

130'000 nm |

|

Max Cylinder Size |

7000 mm |

- |

|

Max Cylinder Pipe Diameter |

4500 mm (Closed Center) |

- |

|

Max Cylinder Flange Diameter |

620 mm |

620 mm |

|

Max Product Width |

850 mm |

850 mm |

|

Max Product Diameter (Tandem) |

700 mm |

460 mm |

|

Hydraulic Oil Tank |

600 L |

400 L |

|

Dirty Oil Tank |

600 L |

400 L |

|

Data record |

Digital |

Visual |

Cylinder Removing/Assembling Features

|

Properties |

Values |

|

Maximum Part Weight |

6000 kgs |

|

Maximum Cylinder Size |

Not applicable- Modular Base |

|

Maximum Cylinder Liner Diameter |

620 mm |

|

Maximum Cylinder Flange Diameter |

800 mm |

|

Maximum Product Width |

700 mm |

|

Maximum Product Diameter |

620 mm |

Bench Features

|

Properties |

Values |

|

Maximum Rotational Torque |

65'000 Nm or 130'000 Nm Options |

|

Maximum Rod Pulling Force |

7 Tons |

|

Maximum Tie Rod Pulling Speed |

1200 mm/20 sec |

|

Hydraulic System Pressure |

300 Bar |

|

Hydraulic nutbreaking torque |

6000 Nm @ 8 RPM |

|

Cylinder Pressure Test Capacity |

300 Bar (Standard), 500 Bar (Optional) |

|

Hydraulic Oil Tank |

600L |

|

Waste Oil Tank |

600L |

|

Colour |

Orange – White – Blue |

|

Electrical System |

380/415/460V, 50/60 Hz, 3 phases, 15 amp |

|

Floor Area (15 meter countertop) |

15000mm (U) x 1250mm (G) x 1620mm (Y) |

Features of Cylinder Dismantling Machine For Large Cylinders

Advantages

This Cylinder Disassembly Machine plays an important role in the maintenance of large and heavy cylinders. Especially in industrial applications, it increases the safety of operators while at the same time speeding up repair processes.

Apparatus