What is Hydraulic Power Unit? How does it work?

Basically, a hydraulic power pack is a stand-alone unit consisting essentially of an engine, a reservoir and a hydraulic pump. Using hydraulic fluid to transmit power from one location to another, hydraulic power units can generate a large amount of power that can be used to drive hydraulic machines.

When heavy lifting or repetitive steering force is required, hydraulic power units provide the perfect solution by pulling their power from the area and pressure ratios defined by Pascal's physics law.

Hydraulic technology is widely used in a wide variety of lifting applications in many industries. These include: Trucks, mining, road construction, agriculture, automotive and aviation, just a few of them.

By applying a small amount of force, a hydraulic system can develop a pressure of more than 10,000 psi. This helps lift heavy loads and perform tiring tasks at affordable costs.

In this hydraulic power unit system, I will consider all the important points about these systems. I will discuss the working principles, components, applications, troubleshooting, production process, quality control, cost and future of hydraulic power pack technology.

Whether you are a beginner or an expert, this article is designed to provide easy-to-understand and comprehensive information about hydraulic power pack technology.

Before we discuss the basic components of hydraulic power packs, let's take a quick look at the history of hydraulic technology.

Hydraulic power units are an important component used in hydraulic systems. These units are used to supply and control pressurized fluid in hydraulic systems. They usually include hydraulic pumps, motors, valves and tanks.

Hydraulic power units are used in many industrial applications. These include manufacturing machinery, construction equipment, mining machinery, agricultural machinery and many more. Since these units are used in processes that require large amounts of power, they generally have a high-pressure and durable structure.

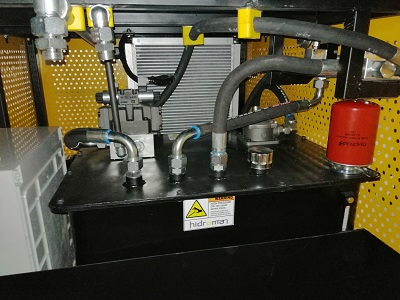

A hydraulic power unit usually includes components such as a hydraulic pump, motor, storage tank, filters, valves and control devices. The pump takes the liquid from the tank, circulates it in the system and creates pressure. The engine provides power to run the pump. Storage tank is used for storage and cooling of liquid. Filters ensure the cleanliness of the liquid, and valves ensure the direction of the liquid and control of the pressure.

Hydraulic power units are designed to provide reliability and performance in complex systems. Therefore, they are widely used in industrial applications.

The hydraulic system is any component that uses a liquid to produce and transmit energy from one point to another in the closed system. This force can be in the form of linear motion, force or rotational motion. It is based on Pascal Laws. Do not worry, you will understand how this law works after our letter to inform the working principle of these power packs. Therefore, when you refer to hydraulic power units, it is basically a system that generates pressure or force based on the above basic features. You can use them in applications that require heavy and systematic removal.

Hydraulic pump units can sometimes be called hydraulic power units, hydraulic power units or hydraulic power units. All refer to the same component. HPU uses different components to generate, transmit, distribute and control this energy.

The components of the hydraulic power unit include:

Electric or diesel engines

Hydraulic valves

Hydraulic oil Tank

Hydraulic gear pumps

Suction Filters, Return Filter and Pressure Filter

Vent cap for filling oil into Hydraulic Reservoirs

Hydraulic Control Block

Electric Control systems such as remote control and wireless remote control

It is these parts that are connected together to form an electrically powered power unit, a single component. Other power units may have more components depending on the complexity of the design.

In the next section you will learn more about these components.

For example, a small hydraulic power unit may have fewer components than those in the heavy lifting industries. It will also depend on the hydraulic power unit design. You will learn about the design process in Chapter 2 and the manufacturing process in Chapter 7. Today, we use power packs in a wide variety of applications, both in our daily life and in a number of production processes.

The main reason for this is:

Cost efficiency

High power transition density

Reliability and security

Flexibility in design

For example, I'm sure you see a small hydraulic jack that lifts heavy trucks. They use a small amount of hydraulic fluid that transmits a large amount of force to lift the truck.

Even big buses and trailers use hydraulic systems in brake systems. With all this in mind, we can continue to classify existing power pack types available on the market.

1.2 Hydraulic Power Pack Types

There are many types of hydraulic power packs on the market. As you will later notice in this hydraulic power pack eBook, the classification may depend on the structure, function and size of the power pack.

Lets start:

Type of Power Units by Design First, I would like to state that the construction design will determine the primary function of the hydraulic system. In general, in this section, I will introduce you to two main categories:

Single acting hydraulic cylinder

Double-acting hydraulic cylinder

This Chapter will give you more information about their functions in section 1.3, but before that, let's give a quick overview of single and double acting hydraulic cylinders.

Single acting hydraulic cylinders

In single-acting hydraulic cylinders, the hydraulic fluid acts on only one end of the piston. Therefore, the cylinder uses compressed air, a mechanical spring, a flying wheel, or a gravitational load to push the piston back to its original position (retraction).

Double-acting hydraulic cylinders

A double acting power unit is where working hydraulic fluids alternately act on both ends of the piston. That is, it uses hydraulic power to extend and retract the piston.

Power Unit Type by Primary Applications

This is a common classification criterion, where you can identify a particular piece of equipment depending on the nature of its application. Again, you will learn more about this as I discuss specific applications of hydraulic power packs in this Part 1, part 1.4.

I will list all possible uses of these hydraulic systems.

Types of Power Packs by Size

In most cases, it is common to describe this hydraulic equipment by size or capacity. Basically, the classification criteria explain various performance characteristics.

The main common performance features include:

Flow rate

Operating pressure

Tank volume

Electric motor power

Liquid type, i.e. mineral oil HL or HLP

I will focus on four main criteria for the scope of this hydraulic power unit eBook:

What are the Types of Hydraulic Power Units?

1) Micro Power Units

Micro hydraulic power units are suitable for applications where space is limited. They are portable because of their small size.

It is compact in size and available in single or double action. Due to their flexibility, you can operate them with single or double action without having a solenoid control valve.

All you have to do is reverse the motor movement. These types of micro power packs have double pressure relief valves that offer separate control options.

In addition, the double check valve reduces the effects of noise and induced pressure. Tank capacities can range from 0.1 to 3 liters.

The micro hydraulic power pack uses 150 to 800 watt DC motors to run hydraulic pumps.

Remember, all these features may vary depending on the manufacturer.

2) Mini Power Units

Mini hydraulic power units are suitable for mobility applications. It is slightly larger than micro power unit units. Space is never a problem for these hydraulic power units. Due to their size, they are also called small hydraulic power units or small hydraulic power units.

Available in different configurations, such as horizontal or vertical mounting, with a reservoir tank capacity ranging from 0.8 to 30 liters. It uses DC 0.8kW to 4.0kW motor or AC 0.75kW to 7.5kW motor. The voltage of DC motors is DC 12V / 24V or DC36v / 48v, and the voltage of AC motors is AC 110V / 220V / 230V / 380V / 415V.

With the advancement in technology, there are portable hydraulic power units with remote control options.

3) Standard Hydraulic Power Units

Standard hydraulic power unit units are designed for in-house operations. They are mainly used for industrial applications. Such hydraulic power units create huge power and high flow rates. They can lift heavy loads for a long time.The tank capacities are about 180 liters and the flow rate is about 100 liters / minute. In most cases, the motor power of most standard hydraulic power packs is about 30kW.

4) Hydraulic Power Unit Stations

Hydraulic power station stations are designed for certain applications. These include sewage treatment, construction and mining applications. For the most part, it is available in custom designs to meet the specific requirements of any unique application. In general, these are the main types of hydraulic power packs available on the market. As you can see, as the dimensions increase, their capacity and strength also increase. Next, I would like to introduce you to the various functions of hydraulic power packs. This will make it easier to understand what you will learn in Chapter 2 of this eBook.

Standard or Special Power Unit Design

Designed to work in a wide and varied application The relevant Fluid Power standard and special hydraulic power units are the task. From simple motor pump units to multifunction power pack assemblies, we can provide solutions that meet our customers' performance, quality and cost expectations.

Continuing investment in design and production, with our extensive application and engineering experience, not only allowed us to develop our latest standard hydraulic power packs, but also to our OEM customers, especially in terms of flexibility, power, control and size.

Compact, Quiet and Efficient Hydraulic Power Units

By listening to our customers and focusing on efficient operation, our existing hydraulic power units are the most compact and advanced designs to date. By guiding our designs, we believe that the installed power must be transmitted effectively and efficiently. This is especially important in today's world, where energy cost reduction and minimum environmental impact are very important. Our specification for high quality, specially developed and precisely manufactured parts allowed us to create hydraulic power packs that are considered to be quiet during operation. This additional advantage allows us to provide solutions for markets and applications where noise is a problem.