What is Hydraulic System, How Does Hydraulic System Work?

Hydraulics is a power transmission system using fluids (usually hydraulic oils). Hydraulic systems enable the transmission of fluid under pressure and its conversion into mechanical power. These systems usually consist of a hydraulic pump, pipelines, valves, cylinders and other components.

Some of the advantages of hydraulic systems are:

1. High Power: Hydraulic systems offer the ability to apply a large force with a small movement. This feature is extremely useful in applications such as lifting heavy loads.

2. Precise Control: Hydraulic systems allow parameters such as pressure and flow to be controlled precisely. This provides a significant advantage in operations requiring control.

3. Durability: Hydraulic systems are often constructed using fluid-resistant metal pipes and components, making them durable and long-lasting.

4. Various Applications: Hydraulic systems are used in many different areas, from construction machinery to industrial machines and vehicles. Thanks to their flexible structure, they can adapt to various applications.

Hydraulic systems are widely used in many industries. The use of hydraulic systems is quite common in areas such as construction, mining, automotive, aviation, maritime, agriculture and manufacturing. These systems play a critical role in many industrial applications by providing a powerful, efficient and flexible method of power transmission.

Hydraulic;

As a word, it is derived from the word or hydor su in Latin.

Hydraulic;

Examines the behavior of applied fluids (applied mechanics).

Hydraulic systems;

The hydraulic system is a system that provides energy transfer and control using fluid pressure. Essentially, a liquid (usually oil) is moved under pressure in a pipeline or tube, and this pressure is used to perform desired work through a series of mechanical parts such as pistons, cylinders, valves, and engines.

Basic components of hydraulic systems include hydraulic pumps (creates pressure), hydraulic cylinders (provides movement), hydraulic valves (controls fluid flow), accumulators (regulates pressure fluctuations), filters (cleans fluid), and pipelines.

These systems have a wide range of uses. Hydraulic systems are used in many areas, from construction machinery to the automotive industry, from factory equipment to agricultural machinery. They are preferred in many applications because they are strong, precise and durable.

Due to the fact that it transmits forces and movements more easily and efficiently than friction systems, hydraulics have been widely applied in machine manufacturing and industrial applications in the second half of the 20th century.

CONTINUITY (Venturi Theorem)

Hydraulic systems have a wide range of uses in many different industries and applications. They are preferred in many areas because they are functional and reliable, provide high power transfer and controllability. Here are some areas of use of hydraulic systems:

1.Construction and Road Construction: Cranes, excavators, loaders and other heavy construction machinery are areas where hydraulic systems are commonly used. These machines use hydraulic cylinders and pistons to lift, move and shift large loads.

2.Automotive Industry: In cars, trucks, buses and other vehicles, hydraulic systems are used in many components such as steering, brakes, transmissions and suspension.

3.Factory and Industrial Equipment: Industrial robots, pressing machines, metal cutting machines and other factory equipment are powered by hydraulic systems. Hydraulic systems are widely used in industrial processes that require precise control.

4.Agricultural Machinery: Tractors, combine harvesters, irrigation equipment and other agricultural machinery are areas where hydraulic systems are commonly used to provide energy and ensure functionality.

5.Maritime and Port Equipment: Cranes, lifting equipment, ship steering systems and other marine equipment operate with hydraulic systems.

6.Aerospace Industry: Many aerospace applications, such as aircraft landing gear, flight controls and rocket launch systems, are enabled by the reliability and powerful performance of hydraulic systems.

Hydraulic systems play a critical role in transferring energy reliably, lifting large loads, controlling precise movements and performing a range of industrial processes.

The flow rate of the liquid flowing through a different pipe is constant. Therefore, it is seen that the velocity of the liquid increases in narrow sections and decreases in wide sections.

Description of Hydraulic System

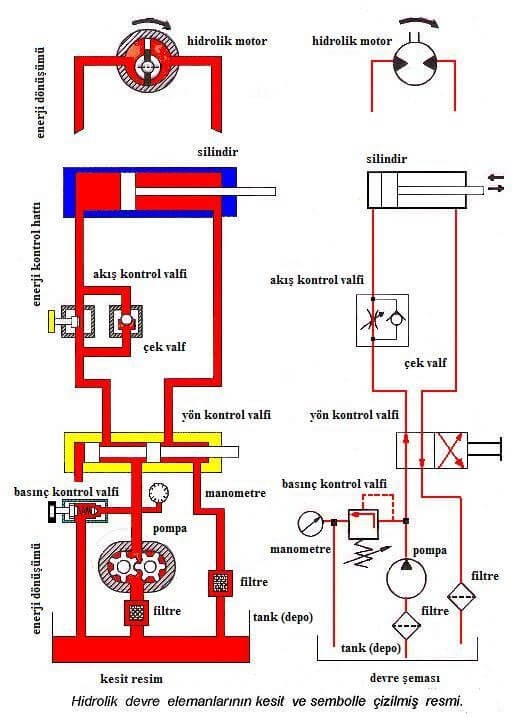

The structure formed by the elements which operate a mechanism with the transmission of pressurized fluid power is called hydraulic system.

The hydraulic pump in the hydraulic system absorbs the oil from the tank and directs it to the system with effective pressure. If the system pressure is higher than the designed value, the system is secured by providing the return to the tank from the Pressure Adjustment valve. The moving user element operates the machine to which it is connected. The speed of the machine can be changed by adjusting the flow rate of the oil passing through the flow control valve.

The flow and return paths of the oil are alternated by the directional control valve in order to allow the user to move back and forth.

The main parts of the hydraulic circuit are:

1- Tank

2- Pump

3- User Elements (Cylinder - Hydraulic Motor etc.)

4- Valves

5- Accumulators

6- Pipe - Hose- Fittings

7- Sealing elements

8- Filters

9- Cooler

10- Accessories, Indicators

Since we need to have information about the working methods of each of the hydraulic system equipments, we will have a separate hydraulic blog about all the hydraulic system circuit elements.

Coming soon, we will publish detailed articles about the following topics.

What is a Hydraulic Pump?

How does the hydraulic pump work?

What is a hydraulic valve?

How does the hydraulic valve work?

What is Hydraulic Cylinder?

How does Hydraulic Cylinder Work?

What is a hydromotor?

How does the hydromotor work?

What is Hydraulic Oil Tank?

Hydraulic Oil Tank

What is Hydraulic Hose?

How to Choose Hydraulic Hose?

Hydraulic Hose